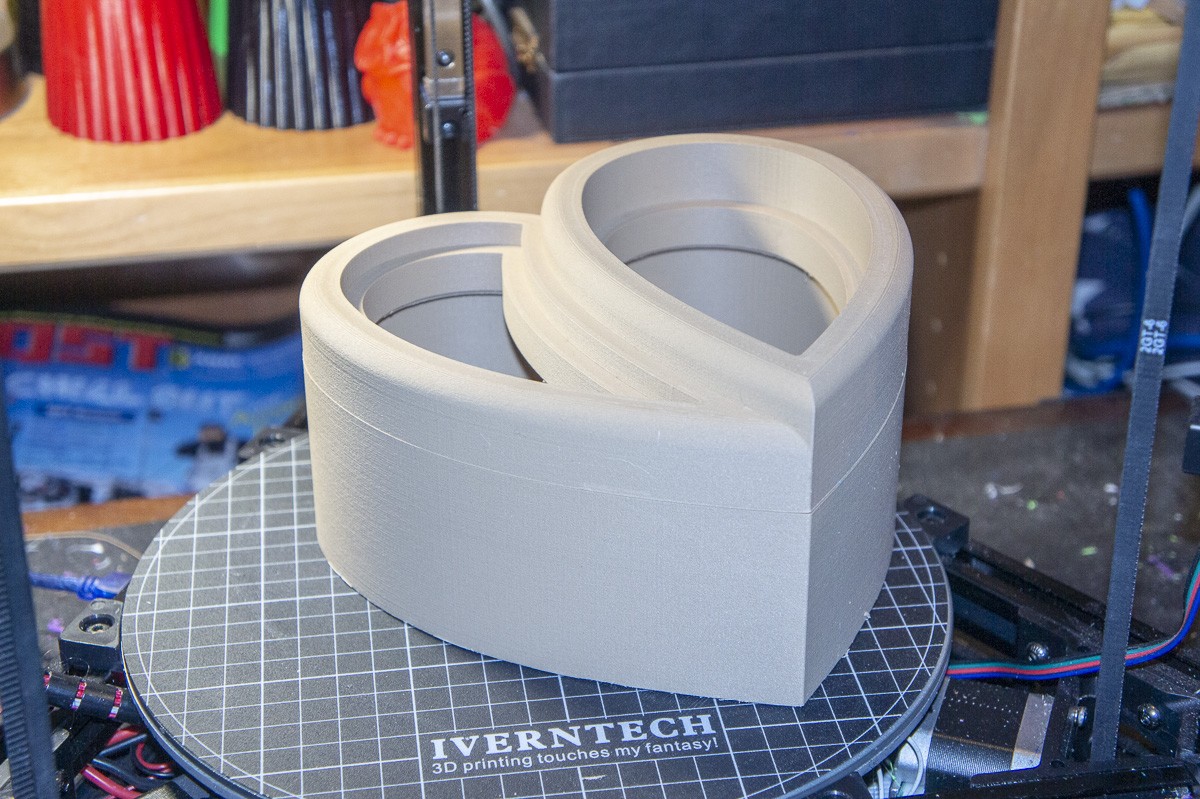

This is a Jewel

Not one of my designs but it is how I would design a box like this. It is large, thick walled, and heavy. It's also printed with PLA/wood. Hatchbox brand in this case..

Presently a work-in-progress and will require a lot of material and printing time. But that is OK. I have always maintained that 3D printing is not a race to see how fast the printer can run. It's all about how well it can print. Fast is not a prime requirement.

The source files are here on Thingiverse: https://www.thingiverse.com/thing:3304456

The top shown in the picture took almost 11 hours to print. The bottom is now on the printer and will run for about 16 hours. More info on this project will be coming...

Seven hours run-time so far.Projected to be fifteen and three quarters, Layer height is 0.20 MM, three shells, infil is 20% with 125% infill extrusion width. Will consume 250 grams of material (.55 pounds).

The bottom is finished printing after almost 16 hours. Looks good! A light sanding and it will be ready for the finish application. The Kossel Delta printer is doing a super job.

Trial fit of the top shows all is well. Not a tight press fit, but easy on and off without being "loose". This is a full size print so resizing may affect lid fit. Gaps resize the same as the resize proportions. I am now printing the flowers! Very cool!

Looks like angel-hair spaghetti and clams on a crescent shaped dish.

It cleaned up, but not a nice as I would really like. I'll see how it looks after the staining and probably some heavy clear coat.

The big flowers are still printing but they are not doing any better. The petals are very fragile looking in the .STL file. There is still a lot of webbing. Maybe a cooler print temperature and longer length retraction could clear up this mess. I may print again if it looks as bad as it seems now...

Must have been a tarantula hiding in the rose bush spinning a web. Boy is that UGLY!

Well, it cleaned up. I am going to see if I can get a better, no strings attached print. New spool coming in tomorrow... If you squint a little, it doesn't look too bad. Hmmm...

Printed this left side 3.5 times. This (hopefully) is the last one. Much better than the original. Lowered print temp to 190 C. and reduced retraction to 2.75MM. I think the only way to improve it is lower layer height.

Comments 8

This project is a reprint of an earlier design. here is the link to the original: https://www.thingiverse.com/thing:2746313

There is a note found there that reads. "note: adorno izq.stl not is solid object (many problems with boolean in blender) , if your use simplify3d use mesh->separate connected surfaces" Now I find it!

This is a requirement with S3D. I am reprinting the left insert and it made a world of difference. Don't know if it will fix the stringing (I doubt it) so I have reduced temperature to 200 deg.

I've never heard of mesh->separate connected surfaces... who wouldathunk?

Well, that's something to keep in mind if I do a reduced scale version of that this weekend. I was thinking of trying the resin printer on the roses next weekend.

I am going to try the smaller scale of the boxes this weekend. Did you ever consider 0.2 nozzles for the roses?

Mike...

It makes a big difference. I have also discovered my thread problem. Like wrong way Carridigan, I was going the wrong way. S3D says Bordon tube printers need more retraction, sometimes up to 15MM. Uh... wrong in my case. I was going from 5 to 7 before I decided that was the wrong direction! The Kossel is now at 2.5MM and I dropped the print temp from 210 to 190. Now very minor threads (almost none). A few other tweaks, too. Works great on left panel. Big test is when I reprint the big right panel. I need more filament before that.

By accepting you will be accessing a service provided by a third-party external to https://rdblog.tedatum.com/